400-640-2005 timpei@aliyun.com

3Q linear motor high-speed machining center V580 is a high-end CNC machining equipment with advanced technology and simple operation. It has the characteristics of high speed, high rigidity and high feed. It combines rough and precision machining functions with one machine, which greatly reduces the procurement cost of enterprises and simplifies the processing process. And can be widely apply to that fields of high-rigidity drill, vigorous milling, high-speed precision machining and the like. Q linear motor high speed machining center V580 is also called high speed CNC, CNC high speed machine.

Linear motor high-speed machining center V580 standard configuration

CNC operating system CNC operating system |

DD motor four-shaft DD motor four-shaft |

Handwheel controller Handwheel controller |

Roller cam four-shaft Roller cam four-shaft |

Contact tool setting instrument Contact tool setting instrument |

DD motor five-axis DD motor five-axis |

Variable frequency constant temperature oil cooler Variable frequency constant temperature oil cooler |

On-line Measurement System On-line Measurement System |

20-position disc magazine 20-position disc magazine |

Elevated Column Elevated Column |

SMC positive pressure seal SMC positive pressure seal |

|

Note: Symbol " " stands for standard configuration Symbol " " stands for standard configuration Symbol " " stands for optional configuration " stands for optional configuration |

|

Characteristic of V580 Linear motor high speed machining cent

1. Equipped with full closed-loop linear motor, can be used for drilling, high gloss milling and other processing, is a high-speed, high-precision full-face CNC. Equipment.

2. Each axis is driven by a linear motor and equipped with a fag grating ruler to achieve full closed-loop control, which effectively improves the processing efficiency of products. Accuracy and smoothness, and at the same time, the problem of thermal extension caused by the transmission of the screw rod is avoided.

3. The beam is supported by three linear guide rails, which improves the rigidity of Z axis and the stability of X axis movement.

4. Equipped with 120 (30000 rpm) permanent magnet electric spindle, it can be used for vigorous milling, high-speed finish machining and high-speed rigid tapping.

5. Equipped with 20 tool position disc type double servo tool magazine, using manipulator tool change, tool-to-tool tool change time is 1.2 seconds, the manipulator uses a unique buffer technology to avoid the impact on the electric spindle.

Technical parameters of linear motor high-speed machining center V580

| X/Y/Z axis motion positioning accuracy | 0.002/0.002/0.002mm |

| Repeated positioning accuracy of X/Y/Z axis | 0.002/0.002/0.002mm |

| Working stroke of X/Y/Z axis | 500/600/330mm |

| Workbench dimension | 590x620mm |

| Spindle power/torque | ≤11Kw/11.7N.m |

| Distance from spindle nose to worktop | Standard 190-520mm/Elevated 340-670mm |

| Working Load | ≤300Kg |

| Electric spindle speed |

≤30000rpm(?120) Permanent-magnet synchronous |

| Shank Specification | BBT30 |

| Tool magazine capacity | 20 (manipulator tool change) |

| X/Y/Z axis rapid movement speed | 80m/min |

| X/Y/Z axis cutting feed speed | ≤18m/min |

| Driving System | Sadik linear motor |

| Control system | Rhenium nanogram total closing and control |

| Working Voltage | Three-phase 380V/50Hz |

| Air supply pressure | ≥0.55MPa |

| Total weight of machine tool | 5500Kg |

| Each equipment is tested and debugged by ball bar instrument before leaving the factory. | |

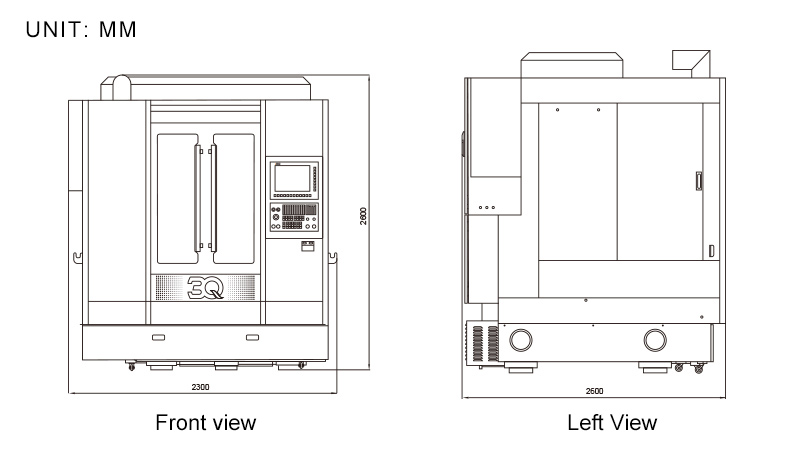

Boundary dimensions of linear motor high speed machining center V580

Phone: +86(0)13761721518

Tel: 400-640-2005

Email: timpei@aliyun.com

Add: Yandu district, yancheng city in jiangsu province big ZongHu universal double gen garden especially ih Hong Kong (M)