400-640-2005 timpei@aliyun.com

The 3Q tool library precision carving machine XT10 has functions such as high-precision carving, milling, grinding, drilling, and cutting. This model has an automatic tool changing function, suitable for processing large format non-metallic materials and metal materials such as aluminum and copper, electronic fixtures, acrylic panel cutting, large panel material molds, etc. The 3Q tool library precision carving machine XT10 is a distinctive and powerful precision CNC machining equipment with features such as in machine measurement and intelligent correction. Precision engraving machines can also be called precision engraving machines, precision engraving and milling machines, etc.

Characteristics of Tool Magazine Carving Machine XT10

Mechanical structure: The crossbeam and column adopt an integrated cast iron structure, and the bed body adopts a floor reinforcement integrated cast iron design, with strong resistance to cutting vibration.

Motion module: The bearing end adopts a branded linear module to improve assembly accuracy, combined with grinding screw and guide rail to maintain high precision and smoothness of the machine tool during high-speed operation.

CNC system: Adopting rhenium sodium gram bus control system to avoid position errors caused by returning to the origin, while improving equipment response speed and resolution, making the high-speed machining of circular arc positions and small line segments more uniform.

High speed electric spindle: adopted Φ 100mm electric spindle ensures torque and rigidity while reducing the weight of the Z-axis, avoiding impact and vibration caused by excessive inertia.

Knife magazine: Adopting a self-developed servo D-type knife magazine, it has better sealing performance, and multiple anti-collision knife safety designs are added, making tool replacement safer and more reliable, and faster.

Tool magazine engraving machine XT10 standard configuration

CNC operating system CNC operating system |

Axis of rotation Axis of rotation |

SMC positive pressure seal SMC positive pressure seal |

On-line Measurement System On-line Measurement System |

Handwheel controller Handwheel controller |

Laser tool setting instrument Laser tool setting instrument |

Contact tool setting instrument Contact tool setting instrument |

36000rpm 36000rpm |

Quantitative pressurizing type automatic lubricating Quantitative pressurizing type automatic lubricating |

|

Heat exchange of electric cabinet Heat exchange of electric cabinet |

|

Constant temperature oil cooler Constant temperature oil cooler |

|

Pneumatic protective curtain Pneumatic protective curtain |

|

Servo tool magazine Servo tool magazine |

|

Coolant circulation system Coolant circulation system |

|

Hand-held start-stop button box Hand-held start-stop button box |

|

Note: Symbol " " stands for standard configuration Symbol " " stands for standard configuration Symbol " " stands for optional configuration " stands for optional configuration |

|

Performance parameters of tool magazine carving machine XT10

| X/Y/Z axis motion positioning accuracy | 0.01/0.01/0.008mm |

| Repeated positioning accuracy of X/Y/Z axis | 0.008/0.008/0.005mm |

| Working stroke of X/Y/Z axis | 800x1000x160mm |

| Workbench dimension | 820x1020mm |

| Distance from spindle nose to worktop | 70-230mm |

| Max Working Load | 100kg |

| Max Spindle speed | 24000rpm(φ100mm) |

| Shank Specification | ISO25 |

| Tool magazine capacity | 10 pack |

| Fast moving speed | 15m/min |

| Max Cutting speed | 10m/min |

| Driving System | Absolute value servo system |

| Working Voltage | 380V/50Hz |

| Control system | Nanobus control |

| Working Voltage | 380V/50Hz |

| Air supply pressure | ≥0.55MPa |

| Total weight of machine tool | 2300kg |

| Each equipment is tested and debugged by ball bar instrument before leaving the factory. | |

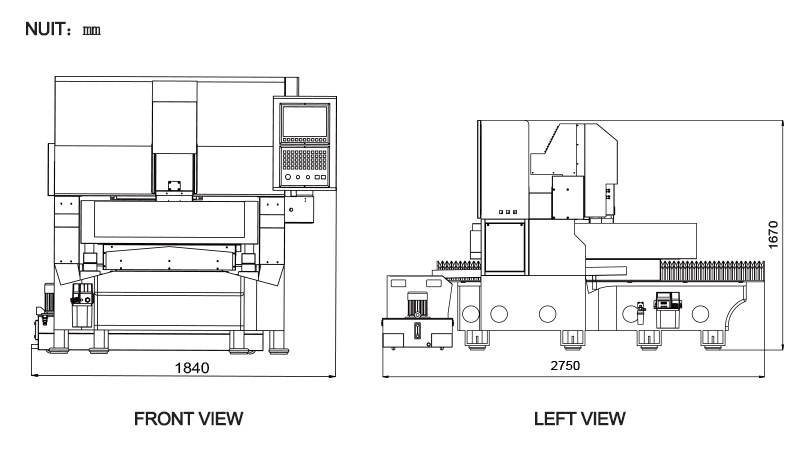

Overall dimension of cutter magazine fine carving machine XT10

Phone: +86(0)13761721518

Tel: 400-640-2005

Email: timpei@aliyun.com

Add: Yandu district, yancheng city in jiangsu province big ZongHu universal double gen garden especially ih Hong Kong (M)