400-640-2005 timpei@aliyun.com

3Q five axis five linkage machining center RV280, from rough to fine, completed in one go. Can perform five axis linkage machining, suitable for five axis machining of die castings, titanium alloy precision parts, precision molds, optical molds, and complex hardware components. Especially suitable for five axis machining of 3C highlights, musical instruments, and impellers. Featuring high rotational speed, high rigidity, and high feed rate, it can be widely used in fields such as high rigidity drilling, vigorous milling, and high-speed precision machining. The integration of rough and precision machining functions with a single machine greatly reduces the procurement cost of the enterprise and simplifies the machining process. It is a high-end CNC machining equipment with advanced technology and simple operation. The 3Q five axis five linkage high-speed machining center RV280 is also known as a five axis high-speed CNC or a five axis CNC high-speed machine.

Five-axis five-linkage machining center RV280

DD five-axis turntable DD five-axis turntable |

On-line Measurement System On-line Measurement System |

Closed-loop electric spindle Closed-loop electric spindle |

Oil Mist Collector Oil Mist Collector |

CNC operating system CNC operating system |

Laser tool setting instrument Laser tool setting instrument |

Handwheel controller Handwheel controller |

|

Contact tool setting instrument Contact tool setting instrument |

|

Constant temperature oil cooler Constant temperature oil cooler |

|

Heat exchange of electric cabinet Heat exchange of electric cabinet |

|

20-position disc magazine 20-position disc magazine |

|

Screw chip removal machine Screw chip removal machine |

|

Rigid tapping Rigid tapping |

|

RTCP tip following RTCP tip following |

|

Note: Symbol " " stands for standard configuration Symbol " " stands for standard configuration Symbol " " stands for optional configuration " stands for optional configuration |

|

Typical application of five-axis five-linkage machining center RV280

Medical Device Parts

Automobile mould insert

Impeller/scroll

Musical Instrument Accessories

Gear die and parts

Brittle and hard material

Ornaments/Handicrafts

Die Casting Parts

Jig type structural member

Composite processing structural part

Performance parameters of five-axis five-linkage machining center RV280

| Project | Standard Value |

| Model | RV280 |

| X/Y/Z axis motion positioning accuracy | 0.008 / 0.008 / 0.008mm |

| A/C axis motion positioning accuracy | 10″/ 10″ |

| Repeated positioning accuracy of X/Y/Z axis | 0.006 / 0.006/ 0.006mm |

| Repeated positioning accuracy of A/C axis | 5″/ 5″ |

| Working stroke of X/Y/Z axis | 700 / 800 / 330mm |

| Rotation angle of A/C axis | ±120°/ 360° |

| Diameter of table | Φ280mm |

| Machining diameter | Related to A-axis rotation angle |

| Maximum Working Load | 40kg |

| Maximum spindle power/maximum torque | 8.5Kw/9N.m |

| Spindle Nose to Table Distance | 30000rpm(Φ 120)Closed loop |

| Shank Specification | BT30 |

| Tool magazine capacity | 20 pack(Robot tool change) |

| X/Y/Z axis rapid movement speed | 50m/min |

| A/C axis rapid movement speed | 200rpm |

| Maximum X/Y/Z axis cutting speed | 12m/min |

| Maximum A/C axis cutting speed | 50rpm |

| Driving System | Absolute value servo system |

| Control system | Nanobus system |

| Working Voltage | Three phase 380V/50Hz |

| Air supply pressure | ≥0.55MPa |

| Total weight of machine tool | 6000Kg |

| Each equipment is tested and debugged by ball bar instrument before leaving the factory. | |

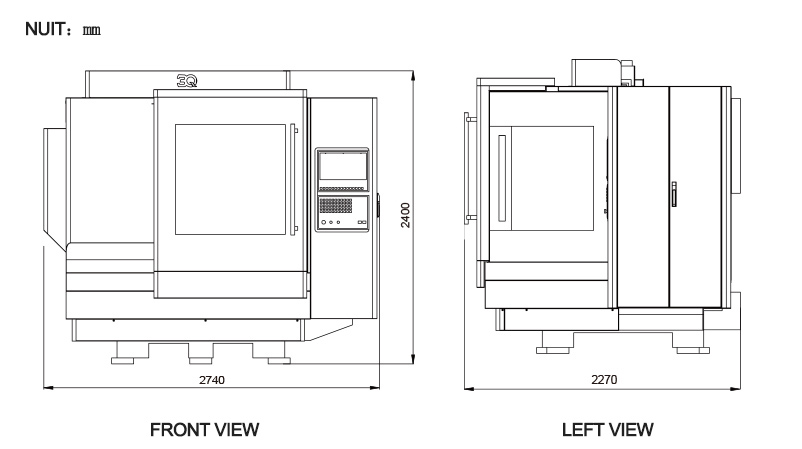

Dimension of five-axis five-linkage machining center RV280

Phone: +86(0)13761721518

Tel: 400-640-2005

Email: timpei@aliyun.com

Add: Yandu district, yancheng city in jiangsu province big ZongHu universal double gen garden especially ih Hong Kong (M)